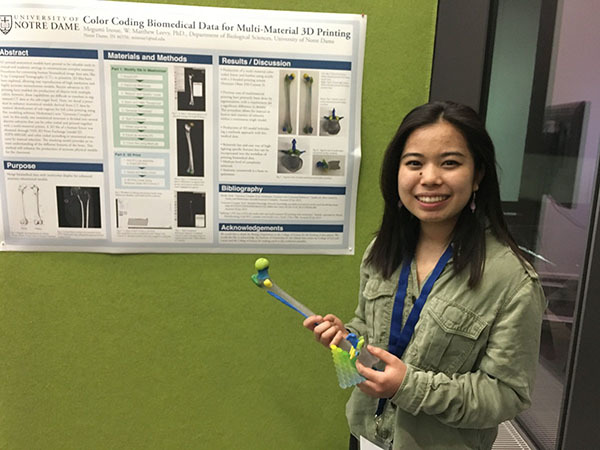

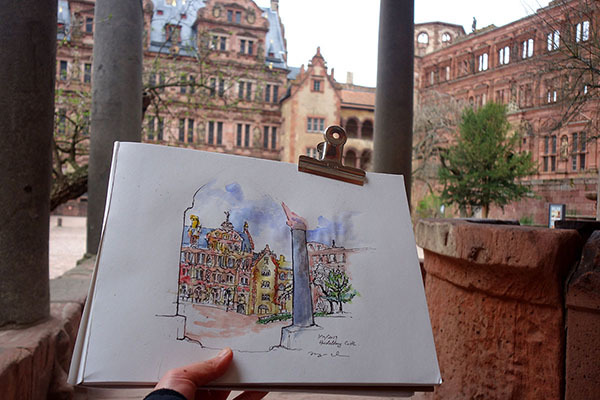

When Megumi Inoue presented her research into how to best colorize 3D-printed anatomical teaching models at a conference in Heidelberg, Germany, last spring, her work allowed her to cross continents as well as academic disciplines.

For this 3D-printing project, the senior from Arcadia, California, and Yokohama, Japan,combined her major in preprofessional studies with her minors in studio art and computing and digital technologies. Drawing on her passion for art, her interest in science, and her work in classrooms and labs, Inoue developed teaching tools that will someday benefit students just like herself.

Most anatomical teaching models are either sculpted from images of the body or cast from other models, Inoue said. However, 3D-printed body parts, based on data files from CT scans, would provide a more precise way to envision the human form than either of these methods. Inoue explained that although doctors use 3D printing to model body parts of individual patients, no one has applied this technology more generally in a teaching setting.

“But I was working in a lab and I knew [about] our capabilities of multimaterial color printing,” Inoue said. “I was also, at the same time, taking an anatomy course and learning about all these different features on the bone, and I wanted to highlight specific features and then color them, using the multicolor printing technology to create enhanced teaching models.”

The lab of W. Matthew Leevy, research associate professor in the Department of Biological Sciences, gave Inuoue the technology and skills to create these accurate models for the classroom, which present exciting practical possibilities. The 3D-printed models are more tangible than just pictures of body parts and more accessible than real specimens, which students have to travel to a lab to see. Also, since students cannot make marks on specimens, color-coded models often display anatomical features more clearly than the real thing.

But before her models could help instruct students on the intricacies of the human body, Inoue received the opportunity to tell other researchers about her work. In March 2019, the College of Science Travel Research Grant and funding from the Institute for Scholarship in the Liberal Arts allowed Inoue to travel to the EMBO Visualizing Biological Data Workshop in Heidelberg, Germany. At the conference, Inoue presented on multi-material printing, the first of two techniques she used to replicate anatomical structures.

“It was really interesting, because the conference for visualization of biological data really draws scientists from a lot of different fields,” she said.

Despite this diversity of research, Inoue reported that out of about 90 posters, there were only three groups who had been working with 3D printing, and even fewer who were working with data from CT scans.

Because of the unique properties of her work, “people were very interested in the different applications that it could have within biology,” Inoue said. Conference participants were especially excited by the fact that she had brought along a physical model to show them. “With that positive feedback, I kept going with the project and added this new printing technology, [binder-jet printing,] which turned out to be better in some ways because it allowed for a greater number of highlights,” Inoue explained.

In addition to presenting at the conference, Inoue published a paper comparing both the multi-material and binder-jet printing techniques in the journal Applied Sciences this February. This success will help Inoue’s work reach even more people. At what she calls “the intersection of art and science,” Inoue strives to make the study of anatomy accessible to all.

Inoue used both her creative and technical skills to colorize her 3D-printed products, ensuring that all of the significant elements of a body part were easy to identify. But as well as changing the color of anatomical structures, 3D printing allows model designers to manipulate the size of body parts, which leads to cool future applications. Inoue imagines that someday, students could carry color-coded mini bone kits around in their pockets and study the body anywhere. These innovative strategies will “make looking at 3D structures and learning from 3D structures a lot easier for students,” Inoue said.

To read Inoue’s article in in Applied Sciences, please visit: https://www.mdpi.com/2076-3417/10/5/1571

To see more of Inoue’s artwork, please visit: https://www.studiomegumi.com/